API 5L X60 PSL 2

Looking for API 5L X60 PSL 2 of API standard Carbon Steel Line Pipe & customize size at Factory Rate?

We are manufacturer, exporter & suppliers of API 5L X60 PSL 2 and supply high quality API 5L X60 PSL 2 in both large and small quantities worldwide & offer you the best prices in the market. We at Himesh Steel have a team of experienced professionals with years of experience in manufacturing.

Content Link:

- • API 5L X60 PSL 2 Specification

- • API 5L X60 PSL 2 Usage

- • API 5L X60 PSL 2 Packaging & Shipping

- • API 5L X60 PSL 2 Price

- • Supplemental Comparison Tables for API 5L X60 PSL 2

- • Other Useful Info

- • Our Inventory

API 5L X60 PSL 2 Specification

| API 5L X60 | (PSL1) | (PSL2) |

| Minimum Yield Strength: | 60,200 psi | 60,200 psi |

| Maximum Yield Strength: | None | 81,900 psi |

| Minimum Tensile Strength: | 75,400 psi | 75,400 psi |

| Maximum Tensile Strength: | None | 110,200 psi |

| Notes: This is a standard line pipe grade specified in API (American Petroleum Institute) specification 5L. | ||

API 5L X60 PSL 2 Usage

American Petroleum Institute standard 5L. API pipes & API 5L X60 PSL 2 are exclusively used for transmission of gas and petroleum products.

API 5L X60 PSL 2 Packaging & Shipping

Packed API 5L X60 PSL 2

Packed API 5L X60 PSL 2

Plastic closes both ends, Hexagonal bundles maximum 2.000 kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and IN in sackcloth with several steel strips, Plastic caps.

Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles or as requested. We can also offer customized packaging for API 5L X60 PSL 2 as per customer's requirement.

Overseas Packaging

Export packaging is geared towards the protection, handling and transport of API 5L X60 PSL 2 by air or sea freight and, as such, shares many characteristics with export and transport packaging. Utmost care must also be taken to make overseas packaging suitable for long periods of storage. It is important for overseas packaging to be designed with ease of handling in mind, so as to ensure API 5L X60 PSL 2 is treated with the utmost care at all times.

API 5L X60 PSL 2 Price

API 5L GR. B Seamless Steel Pipe

FOB Price: US $850-1500 / Ton

Carbon Steel Seamless Pipe API 5L X60 PSL 2

FOB Price: US $400-700 / Metric Ton

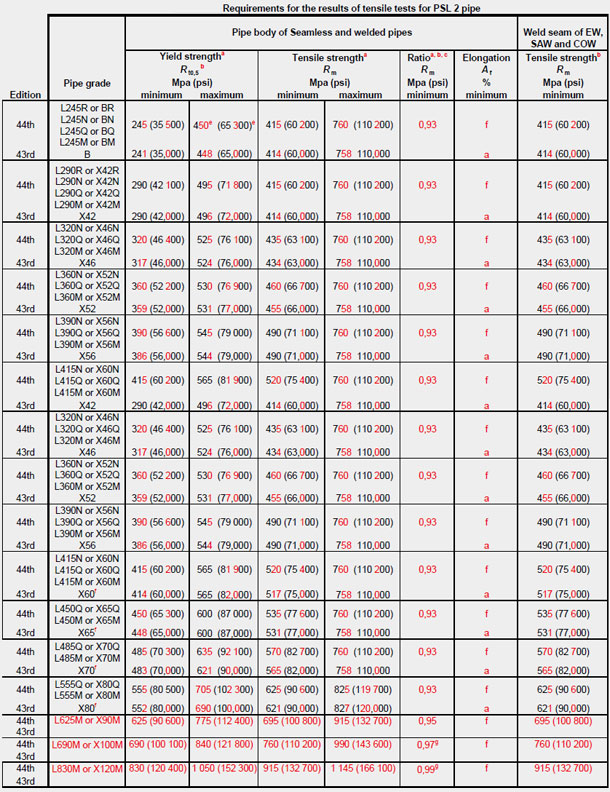

Supplemental Comparison Tables for API 5L X60 PSL 2

| 44th |

a For intermediate grades, the difference between the specified maximum yield strength and the specified minimum yield strength |

| 43rd | b Maximum yield strength for an intermediate grade shall be the maximum for the next higher listed grade. |

| 43rd | C All intermediate grades have a maximum ultimate tensile strength of 110,000 psi (758 MPa).r |

| 44th 43rd |

b For grades > L625 or X90, Rp0,2 applies. |

| 44th 43rd |

C This limit applies for pipe with D > 323,9 mm (12.750 in). |

| 44th 43rd |

d For intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determined for the pipe body using footnote a). |

| 44th 43rd |

e For pipe requiring longitudinal testing , the maximum yield strength shall be <= 495 MPa (71 800 psi). |

| 44th |

f The specified minimum elongation, Af, expressed in percent and rounded to the nearest percent, shall be as determined using the following equation: A f = - - - where C is 1 940 for calculations using SI units and 625 000 for calculations using USC units; - - - |

| 43rd | a The minimum elongation in 2 in. (50.8 mm) shall be that determined by the following equation: e = - - - where C is 1 944 for calculations using SI units and 625 000 for calculations using USC units; - - - |

| g Lower Rt0,5 / Rm ratio values may be specified by agreement for L690 or X100 and L830 or X120 pipe. |

Note that this document is not intended to replace the standards but rather as a tool to facilitate

comparison between standards

Other Useful Info

| CHEMICAL COMPOSITION | |||||||||||

| Mass fraction, based upon heat and product analysis % maximum | CARBON EQUIVALENT a | ||||||||||

| % MAXIMUM | |||||||||||

| Cb | Si | Mnb | P | S | V | Nb | Ti | Other | CEIIW | CEPcm | |

| SEAMLESS & WELDED PIPES | |||||||||||

| L320N or X52N | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | e | 0.43 | 0.25 |

| L320Q or X52Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e | 0.43 | 0.25 |

| WELDED PIPE | |||||||||||

| L290M OR X52M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e | 0.43 | 0.25 |

| MECHANICAL REQUIREMENTS | |||

| Y.S | T.S | ELONGATION | |

| Mpa(psi) | Mpa(psi) | ||

| min | min | min | |

| 415(60 200) | 565(81 900) | f | |

| IMPACT TEST | |||

| AVG. ABSORBED ENERGY | IND. ABSORBED ENERGY | ||

| Min.(joules) | Min.(joules) | ||

| 27 | 20 | ||

Our Inventory

API 5L available ex-stock

Also check our carbon steel inventory

Shipping Worldwide :

We import & export to: